MicroEncapsulation

Temperature Control is at the core of our expertise

Microencapsulation is our strength

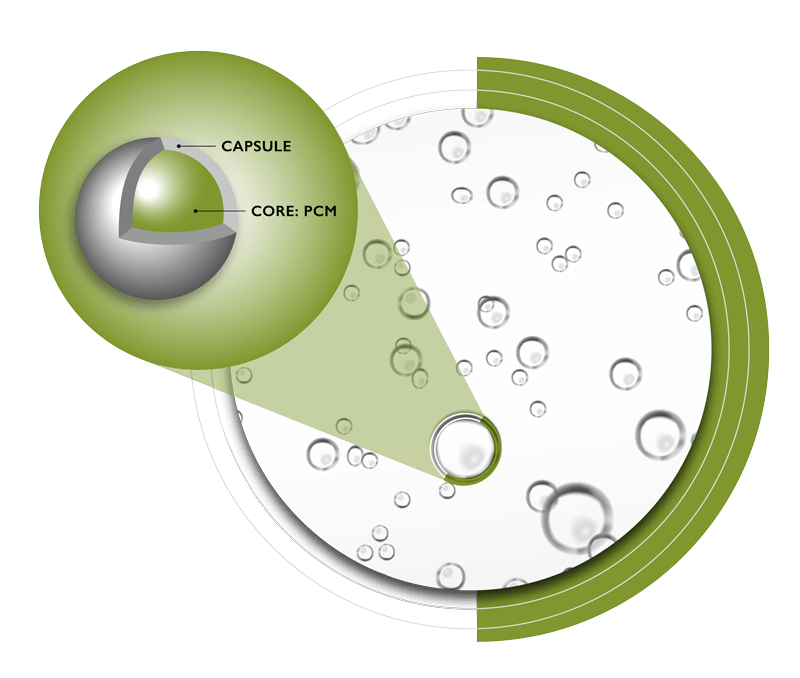

Microtek specializes in the microencapsulation of phase change materials. This process creates a tiny, microscopic container for the PCMs where they are contained in a capsule during both their solid and liquid states.

Phase change material microcapsules can be incorporated directly onto textiles, into latex or PU foams, into adhesives, insulation and even polymers or plastics.

Explore Solutions

Nextek™ patented technology provides high thermal stability in a wide range of temperatures with a robust capsule wall.

Forms

Cake (~70% solids)

Powder (>97% solids)

Temperatures

-10, 6, 18, 24°C ⟺ 28, 32, 37°C

Capsule Components

Melamine based capsule wall with paraffin core

Enthalpy

(varies by temperature)

~ 150 – 205 J/g

Vivtek offers a single solution combining a strong and versatile capsule wall with high thermal stability that can easily disperse in solutionwith a bio-based core – producedfrom agricultural sources, notpetroleum based.

Forms

Cake (~70% solids)

Temperature

29°C

Capsule Components

Melamine based capsule wall with a bio-based, methyl ester core

Enthalpy

(varies by temperature)

~ 150 – 205 J/g

Our Strength is in our offerings

We offer Phase Change Materials in the following forms:

DRY POWDER

WET CAKE

SLURRY

WAYS TO APPLY PHASE CHANGE MATERIAL

PAD COATING

Spraying

PRINTING

DIP COATING

applications include:

Microencapsulated phase change materials provide complete passive thermal management.

Bedding & Textiles

Building and Construction

Electronics

Life Science and Medical Devices

Packaging and Logistics

Personal Comfort and Safety

START MANAGING TEMPERATURE TODAY

Contact our thermal management specialists to discuss your requirements and learn how to kickstart your next project.